Inventory Management - An Overview

Wiki Article

7 Simple Techniques For Inventory Management

Table of ContentsNot known Details About Inventory Management The Greatest Guide To Inventory Management6 Simple Techniques For Inventory ManagementIndicators on Inventory Management You Should Know

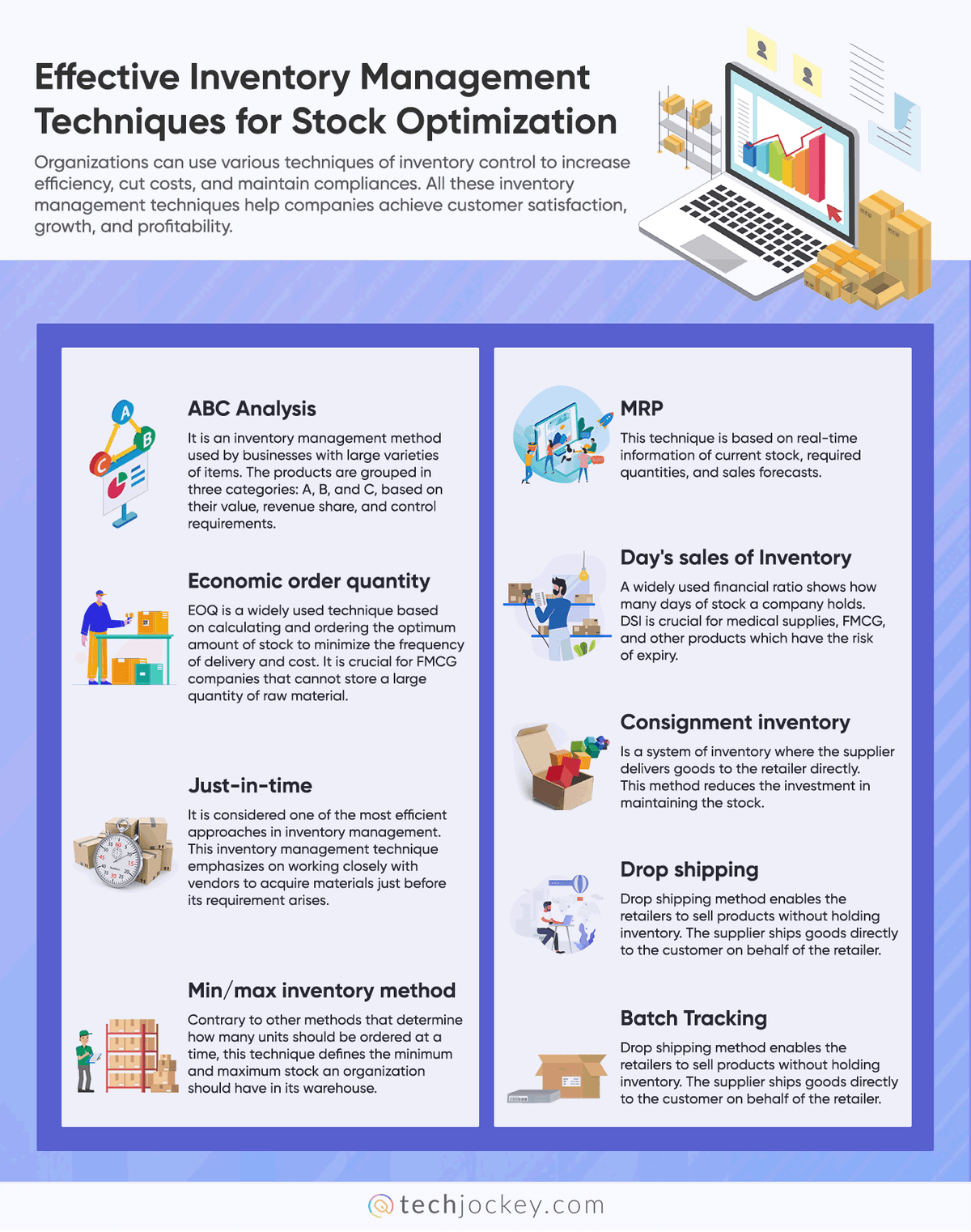

There are 2 main approaches of keeping an eye on inventory: routine as well as continuous. The main difference in between these is how typically data is updated. No matter how commonly you track inventory, you may intend to utilize among the adhering to stock management strategies: ABC Analysis, ABC (Always Better Control) Evaluation is supply administration that separates different products into 3 classifications based upon pricing and is separated right into groups A, B, or C.EOQ Version, Economic Order Amount is a technique used for planning and ordering an order quantity. It involves making a decision pertaining to the quantity of stock that need to be placed in supply at any type of provided time.

FSN Method, This method of stock control refers to the process of monitoring all the products of stock that are not utilized frequently or are not required constantly. They are then categorized right into 3 various classifications: fast-moving stock, slow-moving inventory, and also non-moving inventory. JIT Method, In the nick of time supply control is a procedure made use of by suppliers to manage their supply degrees.

Inventory Management Fundamentals Explained

VED Analysis, VED is a strategy made use of by organizations to manage their inventory. It mainly relates to the monitoring of important and preferable spare parts. The high degree of stock that is needed for production typically justifies the low inventory for those parts. Among the most important aspects that a firm must consider is the precision of the information provided in its stock data sources.Wrike is a project monitoring remedy that can aid you do specifically that. With Wrike's item management devices, you can handle all of your product group's tasks in one place and also get the most out of every task. Wrike's item launch automation aids increase item launches with a structured method.

7 Simple Techniques For Inventory Management

Supply management refers to the procedure of ordering, storing, utilizing, as well as offering a business's supply. This consists of the monitoring of resources, parts, and finished products, as well as warehousing and also processing of such items. There are different sorts of stock monitoring, each with its pros and also disadvantages, relying on a business's demands.Stock monitoring attempts to successfully simplify stocks to prevent both gluts and also lacks. 4 significant stock administration approaches include just-in-time monitoring (JIT), materials demand planning (MRP), economic order amount (EOQ), as well as days sales of supply (DSI).

A shortage of stock when and also where it's required can be extremely harmful. At the same time, stock can be believed of as a liability (if not in a bookkeeping sense).

Recognizing when to replenish inventory, what quantities to purchase or generate, what cost to payas well as when to market and also at what pricecan easily become facility decisions. Tiny organizations will certainly often monitor supply by hand and also figure out the reorder points and quantities utilizing spread sheet (Excel) solutions. Larger services will use specific venture source preparation (ERP) software application.

The Best Strategy To Use For Inventory Management

Proper inventory administration approaches vary depending on the industry. check this site out An oil depot has the ability to store huge amounts of stock for extensive durations of time, enabling it to wait on demand to get. While keeping oil is costly and riskya fire in the U.K. in 2005 brought about countless extra pounds in damages as well as finesthere is no threat that the supply will ruin or go out of style.For companies with complicated supply chains and also manufacturing procedures, stabilizing the risks of inventory excess and lacks is specifically challenging. To accomplish these equilibriums, firms have established numerous approaches for inventory administration, including just-in-time (JIT) as well as materials this page need preparation (MRP). Some firms, such as economic solutions companies, do not have physical inventory therefore needs to count on solution procedure monitoring.

Supply has to be literally counted or determined before it can be placed on an equilibrium sheet. Finished items are finished items conveniently read this offered for sale to a company's clients. Depending on the type of organization or item being analyzed, a business will certainly utilize different stock monitoring approaches.

Report this wiki page